WHERE THE MAGIC HAPPENS...

We design our boats with perfectionism diligence. Safety and security are fundamentals for us. We have our own manufacturer identification code, and we are responsible for the boats that we produce. They are designed and assembled in USA.

QUALITY MATERIALS

Material quality plays a very important role in our boat production, because it is ultimately reflected in the quality of the final manufactured boats. Safe, durable and authentic materials are imperative.

Linear Low Density Polyethylene (LLDPE) is a polymer with widely favorable mechanical and chemical resistance properties. LLDPE has high softening temperature and melting temperature, has good strength and toughness, rigidity, heat resistance, cold resistance is good wait for an advantage, but also has good environmental stress cracking resistance, resistance to impact strength, tear strength and other properties, and acid, alkali, organic solvent and widely used in industry, agriculture, medicine, such as health and daily necessities, etc. The LLDPE we use is from USA. Below are several reasons that explains why we chose LLDPE to be our main construction material:

- Polyethylene is extremely impact-resistant, and we’ll go as far as to say that poly boats are virtually indestructible in the normal course of recreational boating. Smash into a rock jetty, much less a piling, and a poly boat will just bounce right off. Whack the hullsides with a sledgehammer and there’s zero effect (Triumph Company did active tests and demonstrations at boat shows).

- Poly boats are molded, so like fiberglass boats, they can have hulls with complex shapes and compound curves; boats can have molded-in compartments; and large accessories like seat bases or consoles can also be molded. We designed our boats so they can have large storage under the seats. Aluminum boats aren’t molded, so they tend to have much simpler hullforms and accessories must be secured in place with fasteners.

- Waxing and polishing are maintenance chores of the past, when you own a plastic boat. A scrub brush and soapy water is all we’ll ever need to get the boat looking as ship-shape as possible.

- Polyethylene boats are considered more environmentally-friendly than fiberglass, since they can be recycled. Let’s help save the planet AND enjoy fun times on the water!

We design our boats professionally, and they pass through recreational boat testing and compliance inspection program in USA. They are all certified and separately labelled one by one. They maintain order and we ensure safety. Maritime safety is crucial in the industry, and we are proud to be certified by the US Department of Homeland Security, the United States Coast Guard and the Commandant CG-BSX-23 US Coast Guard. We also comply and have an assigned certified letter of the Coast Guard Office of Auxiliary and Boating Safety, Recreational Product Assurance Branch.

Each of our boats have a different Hull Identification Number (Hull ID or HIN). As an official Certified US Boat Manufacturer, we uniquely assign serial number to each boat that identifies it, similar to the VIN on an automobile. We have our own brand of boat.

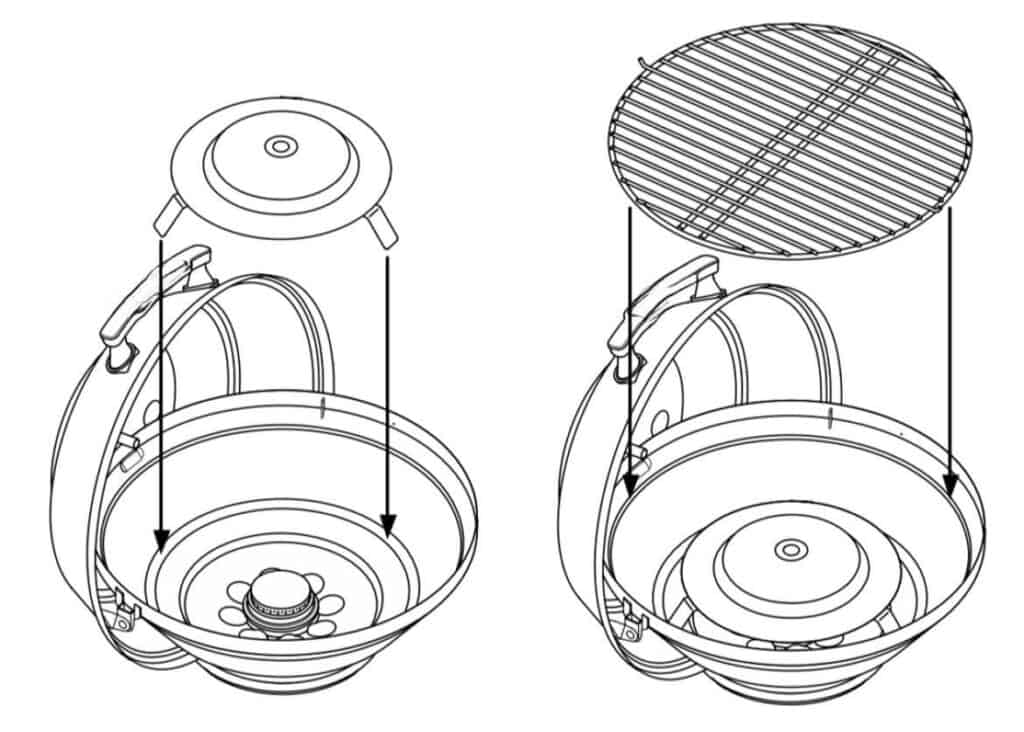

The boat begins as plastic beads, which are loaded into a closed mold. Before we make the boat, we add Fire-retardant material, anti-UV and anti-oxidation materials, and mix them with LLDPE in a certain proportion. Our boats are molded in 1 part in a rotational mold. We use one integral molding. The mold is then heated to melt the plastic and is rotated to evenly distribute the material. After the mold cools, it’s opened and the hull can be popped out.

All Vessels being use within the Unites States must comply with the Code of Federal Regulations (33 CFR Part 188).

TEST REQUIRED BY THE UNITED STATES COAST GUART

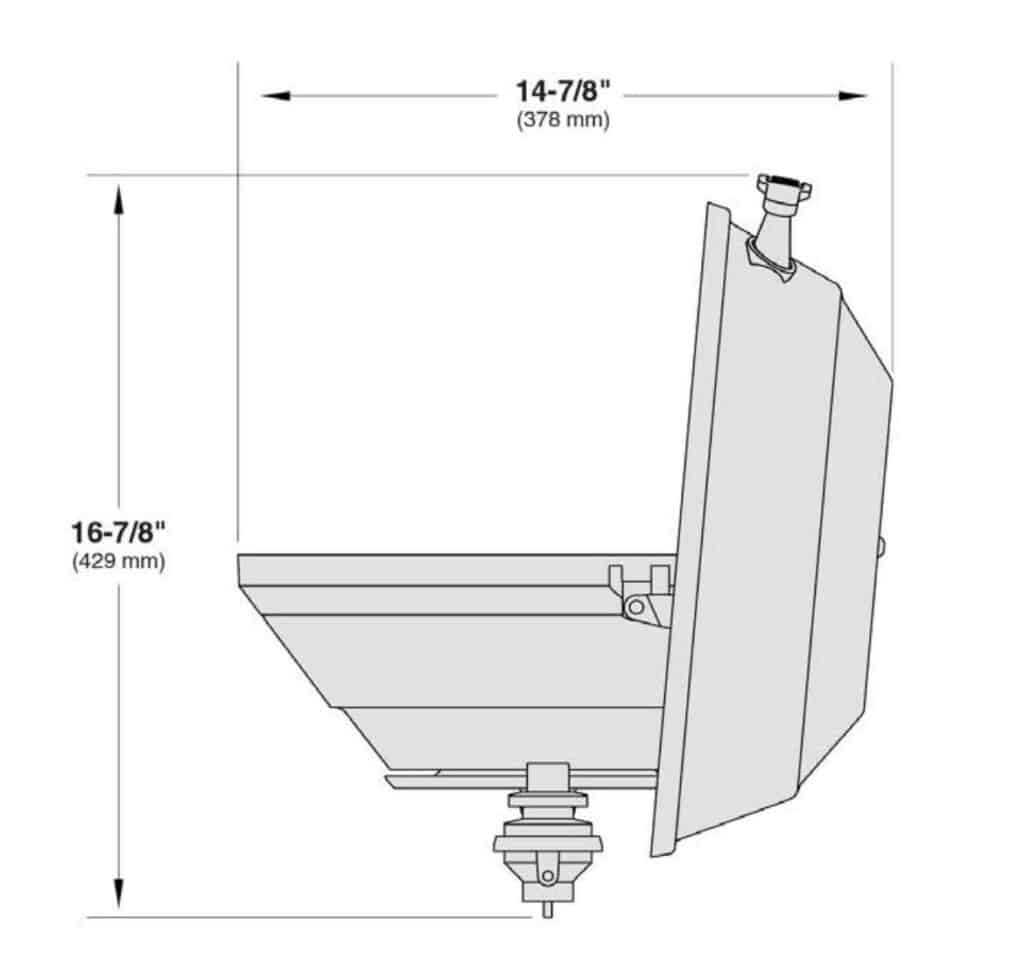

Before putting the boat in the water, we must comply with many tests and regulations. Those tests and research take months before putting a boat alive. In other words, before branding the boat we do multiple steps to establish the capacity figures.

We set up the upper limit of Horsepower, then determine the maximum displacement of the hull. Those tests are done with our Hightech Professional System, and we proceed with mathematical methods. There are many several steps and calculations to do as a manufacturer/importer. No matter if a company decide to build the boats or import them, this process is mandatory in order to use a boat in the US. The boats are then tested in the USCG tank and they shall pass the inspection accompanied by the one and only 34 pages Tankship Inspection Document. And we are happy to say that no matter if it took more than a year, working every day above and beyond to build this project, that we are proud to act in accordance with the USCG, U.S. Coast Guard’s Boating Safety Division (CG-BSX-2) other organizations mentioned above.